Studio Scano, in collaboration with the University of Naples “Federico II”, recently presented a paper titled “Effects of Primary and Secondary Creep Formulations on API 579-1 Residual Life Evaluation” at the 2018 ASME Pressure Vessels and Piping Division Conference (PVP) in Prague (Czech Republic).

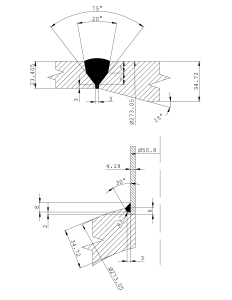

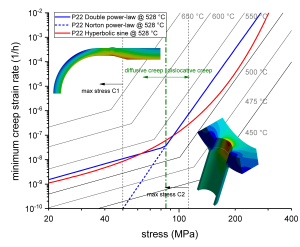

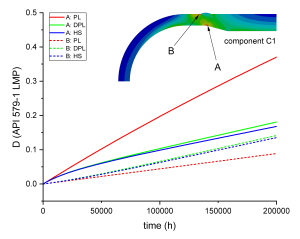

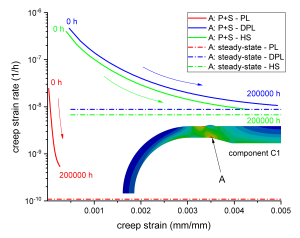

The work focused on how the API 579-1 creep damage, calculated both by the Larson-Miller theory and the Omega method, is affected by the choice of the creep law employed in the inelastic FEA. In particular, the primary creep formulation and the diffusive range of the steady-state (secondary) creep were taken into account for a case-study: a HRSG header manufactured with an ASME SA-335 Gr. P22 low-alloy steel and operated at 528 °C and 10.4 MPa in the creep range.

As a general conclusion for this work, the widespread assumption of negligible primary creep is not straightforward and appears to be inherently dependent upon the modeling strategy involved in the creep assessment (Norton power-law, diffusionrange incorporating relations, e.g., double power-law and Garofolo hyperbolic sine, Omega method).

Scano Lorenzo AuthorThe obtained results can have a significant impact on the Fitness-For-Service assessment of pressure components operated at high-temperatures, in particular high-energy piping and boiler equipment.

The paper is copyrighted by ASME and can be purchased here: